Technology has made it easier than ever to manage vehicle maintenance. Understand the importance of optimising your fleet maintenance to maximise efficiency.

A well-maintained fleet relies on many factors – identifying and addressing issues before they worsen, good quality parts and repairs and efficient management, to mention just a few.

Inefficient maintenance can lead to shorter vehicle lifespans, meaning you pay out for multiple repairs at once and suffer prolonged downtime for your fleet. Thanks to technology, it’s easier than ever to implement an effective maintenance routine. This can increase the time your trucks and trailers spend on the road, boost performance and save money.

Protect your vehicles, drivers and business by optimising your fleet maintenance and improve your proactive maintenance system.

What is fleet maintenance optimisation?

Fleet maintenance optimisation refers to improving the way you care for and manage repairs of your trucks and trailers. It’s all about being aware of when things need fixing or servicing so you can make small repairs before bigger problems occur. This can reduce costs and improve the time your vehicles are on the road.

Optimising your fleet maintenance should lead to repairs and checks happening in a timely, cost-effective manner. There are a number of ways to action this, such as using remote technology to save on costs.

Be proactive rather than reactive and minimise the time your vehicles spend off the road, preventing the need for multiple repairs, which also cuts down on costs.

Optimising your fleet maintenance can reduce vehicle downtime, saving time and money.

Why is it important?

Optimising your fleet maintenance can reduce vehicle downtime, saving time and money. Dealing with multiple large repairs at the same time will be costlier and have a greater impact on your daily processes, with more vehicles off the road.

By having an efficient maintenance programme in place, your business’ reliability should improve, increasing customer satisfaction levels and your reputation as a reliable fleet.

Minimise risk, reduce repair costs and keep your employees delivering goods in a leaner and safer manner. Thanks to the introduction of remote technology, it’s easier than ever to keep your trucks and trailers running at their peak performance.

Common fleet maintenance issues

Keep your fleet running smoothly by checking the most critical issues on a regular basis. Undertake checks regularly. Some of the most common issues include[1]:

- Engine and ECU – As the powerhouse of your vehicle, you should undertake regular checks of

your engines, as well as the Engine Control Unit (ECU). - Fuel contamination – Check for blockages, worn injectors, unexplained engine failure and

corrosion of the fuel tank. This can signal a type of fuel contamination. - Tires – Under and overinflated tires can increase the risk of blowouts, accidents, breakdowns

and compromise driver safety.

There are external factors you can’t plan for too – such as road traffic accidents that occur without warning. You can prepare to some extent by developing a plan of action for every eventuality and make sure your employees are aware of what to do should an accident occur. Equipping advanced driver assistance systems (ADAS) to your vehicles can also help avoid accidents.

Ways to optimise your fleet maintenance

Optimising the way you maintain your commercial vehicles is essential to create a leaner, greener and safer fleet. Modern technology has made it increasingly easy to do so.

Manually checking tire tread is above the safe and legal limit of 1.6mm is a start – though switching tires once they reach 2mm is recommended. OptiTire can automate your tire pressure maintenance, by monitoring pressure to reduce the chance of punctures, blowouts and vehicle damage from driving with under or overinflated tires.

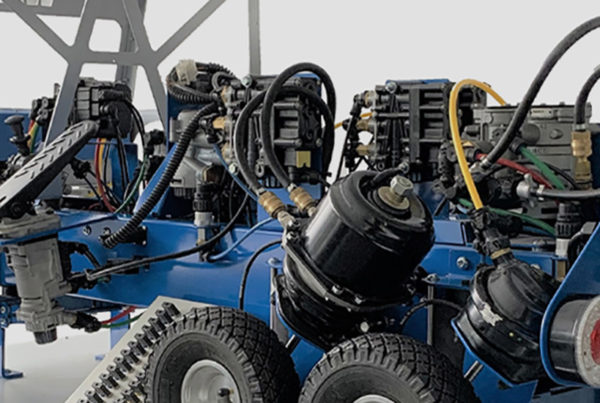

Regular maintenance is key to keep your fleet running at optimum performance. Manually checking vehicles can take up a significant amount of time. TX-DIAGNOSTIX optimises many of these checks without taking trucks off the road. It performs ongoing checks of the key vehicle functions, so you can ensure your fleet is without fault while sat in the back office.

Working trailers are an important part of any fleet too. TX-TRAILERPULSE speeds up trailer maintenance by connecting to the trailer’s EBS and delivering real-time health data. You can plan ahead for repairs to prevent breakdowns and improve trailer performance on the roads.

Keep your fleet running smoothly by checking the most critical issues on a regular basis.

Fleet checks and repairs

Pre-trip checks are still important for drivers to make sure they will have a safe and efficient journey. This includes inspecting everything from cargo load optimisation to the security of any locking mechanisms in place, alongside regular walkaround checks[2] like:

- Mirrors and windows

- Steering

- Brakes

- Lights

- Seatbelts

- Fuel leaks

- Liquid levels

- Windscreen wipers

Using workshops with qualified mechanics when any maintenance issues do arise also offers the quickest way to fix problems. This can reduce the time vehicles are off the road and ensure the best possible repairs are made, to avoid the same problem happening again. Diagnostics and product training for mechanics can improve their skills to enable them to identify and fix a range of issues in the workshop quickly.

By regularly checking and addressing performance issues, you can easily prevent small issues becoming costly, time-consuming problems. Investing in technology is one of the best ways to reduce downtime and optimise your fleet’s maintenance.